In a Texas A&M University Turbomachinery Laboratories study titled, “Piping Vibration Analysis” the authors state, “Piping vibration failures have been one of the major causes of downtime, fires and explosions in industrial plants…”

Excessive vibrations can cause leaks, fatigue failures, high levels of noise and lead to machinery downtime. These failures can accumulate to millions of dollars in losses and create a dangerous work environment.

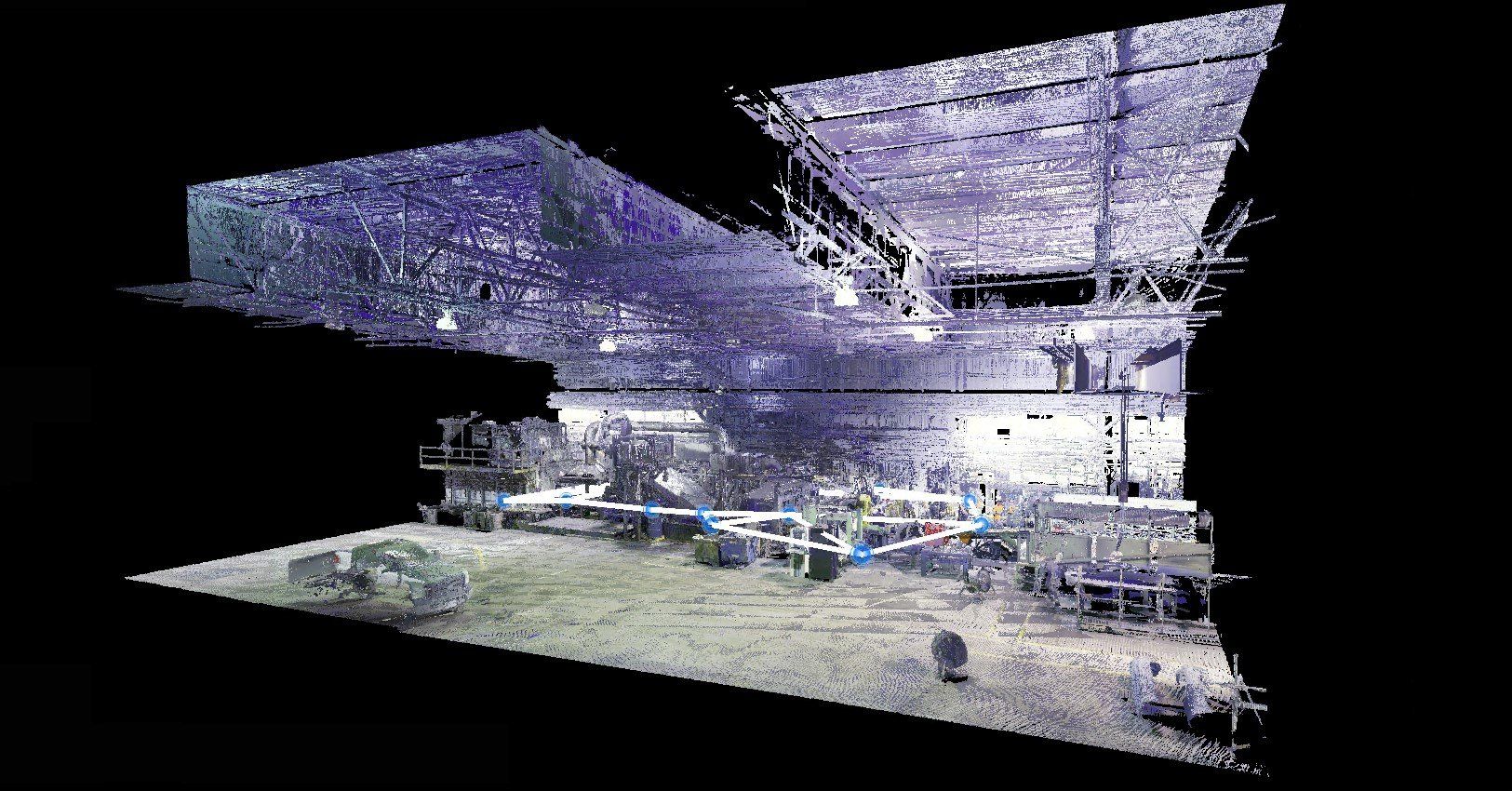

Alloy Mechanical Inc. can provide on-site analysis of your environment to record high-speed visual reviews of your mechanical and/or piping infrastructure. These recordings are reviewed to determine range of motion and vibration frequencies.

Once discovered, facilities can make informed decisions regarding remediation. Alloy’s skilled team of engineers and operators can assist with remediation if requested.

Contact Alloy to discuss our capabilities or learn how we can assist you with your needs.

Alloy Mechanical Inc.

contactus@alloymechanicalinc.com

708.251.8940

FIND OUT MORE ABOUT ALLOY MECHANICAL

17865 Chappel Ave., Lansing, Illinois 60438

admin@alloymechanicalinc.com

708.251.8940